- Forums Home

- >

- Inventor Community

- >

- Inventor Forum

- >

- Re: Sheet metal elbow pipe - how to cut it in half and unfold it?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

Sheet metal elbow pipe - how to cut it in half and unfold it?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

Hi, have you tried using the unwrap command in Inventor 2020?

I have Inventor 2018, so I can't try to reach a flattening of the surface. You cannot achieve a flatPattern in the conventional way.

I hope this helps. regards

Please accept as solution and give likes if applicable.

I am attaching my Upwork profile for specific queries.

Sergio Daniel Suarez

Mechanical Designer

| Upwork Profile | LinkedIn

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

As suggested by @Sergio.D.Suárez , try adjusting the parameters in Unwrap and see if you get a "close enough" result.

-----------------------------------------------------------------------------------------

Autodesk Inventor 2019 Certified Professional

Autodesk AutoCAD 2013 Certified Professional

Certified SolidWorks Professional

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

To put it simply, Inventor sheet metal at this point can only provide accurate flat patterns of parts formed by brake press and straight roller, any forming that stretches the material in more than one direction at once typically cannot be flattened without problems getting in the way. The unwrap method as Sergio and Mather suggested is your next option.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

Thank you all for replying.

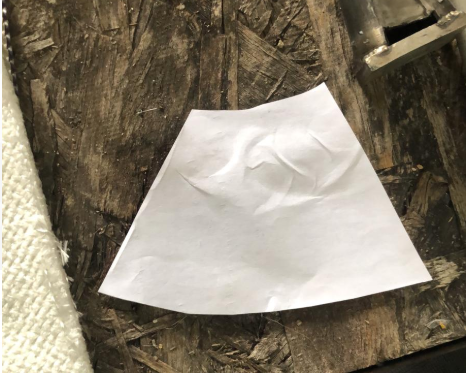

Unwrap created some weird results, using rigid frame on the lower arc it made everything too big:

Without the rigid edge it created something resembling what I need:

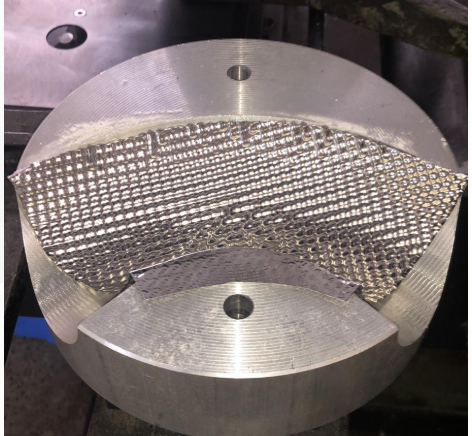

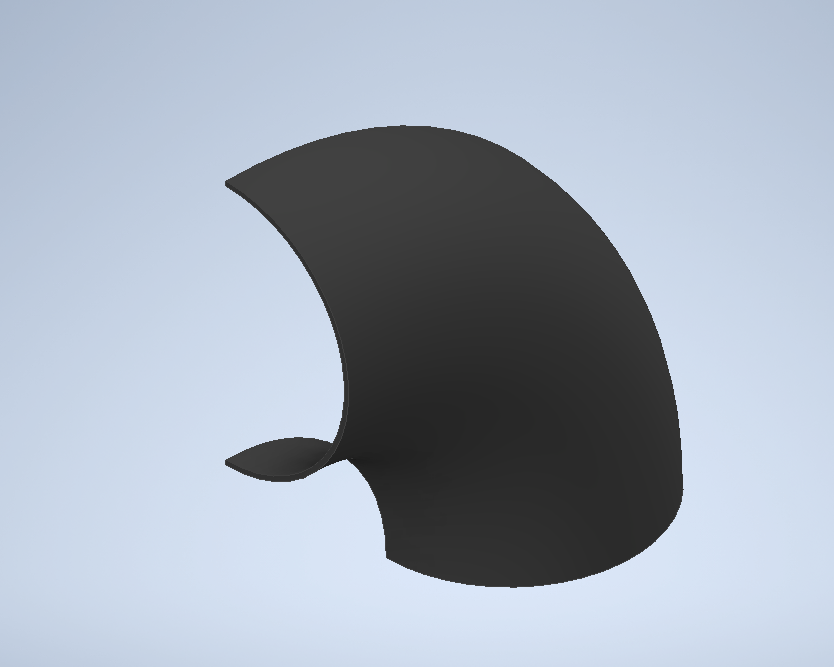

though as you can see there's way too much material on lower arc and a bit too little on the upper arc. Now I'm trying to get the 'flat pattern' to work, but when I create a flat pattern from something like this:

it makes literally a rectangle material:

I've attached a file of the sheet metal part I'm trying to use flat pattern on, maybe there's something I didn't tick? Or is it normal behaviour and I can't get it to 'flatten' the part?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

You will not get a correct flat pattern of that part.

-----------------------------------------------------------------------------------------

Autodesk Inventor 2019 Certified Professional

Autodesk AutoCAD 2013 Certified Professional

Certified SolidWorks Professional

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report

Hi! The rectangular flat pattern is a representation of an unrolled elbow. The rolled (Contour Roll) shape created in Inventor Sheet Metal is meant for keeping the unfold length of linear extensions on both ends intact. The roll itself is not meant to be flattened.

Many thanks!

Johnson Shiue (johnson.shiue@autodesk.com)

Software Test Engineer

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

Forums Links

Can't find what you're looking for? Ask the community or share your knowledge.